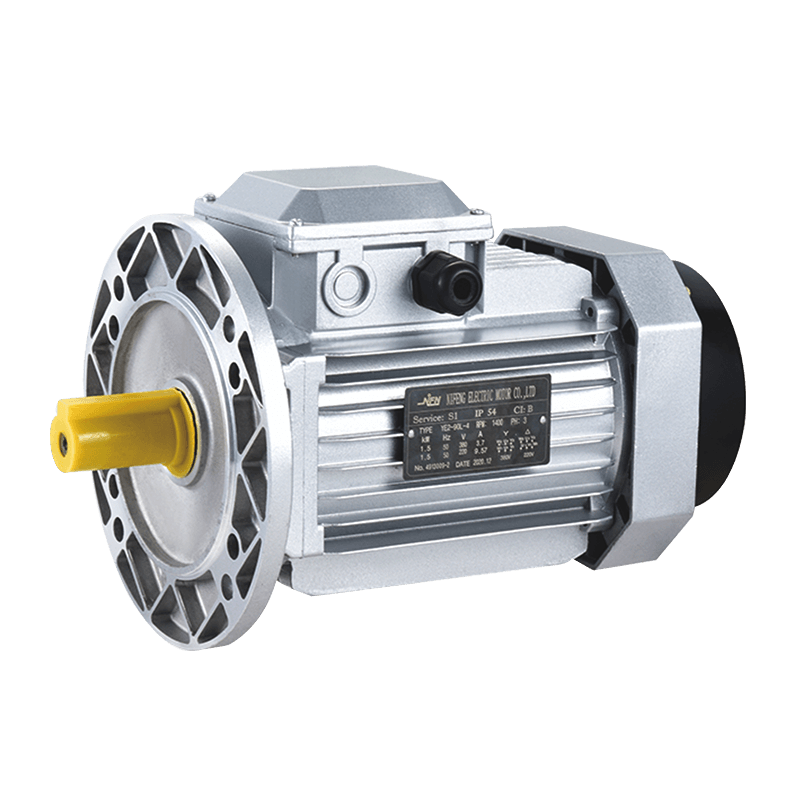

The aluminum shell high-efficiency asynchronous motor epitomizes the fusion of two critical elements: advanced motor technology and lightweight aluminum construction. High-efficiency motor design is achieved through meticulous engineering, optimizing the motor's components to minimize energy losses and maximize power conversion. The integration of an aluminum shell further elevates its performance by leveraging the unique properties of this lightweight yet robust material.

This marriage of efficiency and innovation addresses two significant challenges in motor technology: energy consumption and environmental impact. By utilizing lightweight aluminum and enhancing efficiency, these motors contribute to energy savings while reducing greenhouse gas emissions, aligning with the global push for sustainability.

Mechanics and Working Principles

The mechanics of the aluminum shell high-efficiency asynchronous motor encompass several key components that contribute to its performance:

Aluminum Shell: The lightweight aluminum shell not only reduces the overall weight of the motor but also enhances heat dissipation, contributing to improved thermal management.

Stator and Rotor Design: The motor's stator and rotor are optimized for efficiency, minimizing energy losses and maximizing power output.

Advanced Windings: High-quality windings and insulating materials further enhance efficiency while ensuring reliable performance.

Bearings and Lubrication: Precision bearings and efficient lubrication systems reduce friction, minimizing energy wastage and extending the motor's lifespan.

Applications Across Industries

The versatility of aluminum shell high-efficiency asynchronous motors translates to a wide range of applications:

Industrial Manufacturing: These motors power conveyor systems, pumps, fans, and compressors, driving the efficiency of production processes.

Energy Generation: Aluminum shell high-efficiency asynchronous motors find application in power generation, enhancing the efficiency of generators and turbines.

HVAC Systems: Heating, ventilation, and air conditioning systems benefit from the improved efficiency and reduced energy consumption of these motors.

Renewable Energy: Wind turbines and solar tracking systems utilize these motors to optimize energy capture and conversion.

Water Management: In water treatment plants and pumping stations, these motors contribute to efficient water distribution and wastewater management.

Advantages and Benefits

Energy Savings: The primary advantage of aluminum shell high-efficiency asynchronous motors is their ability to significantly reduce energy consumption, leading to cost savings and environmental benefits.

Reduced Emissions: By operating more efficiently, these motors help reduce greenhouse gas emissions, contributing to a cleaner and more sustainable environment.

Enhanced Performance: The combination of advanced motor technology and lightweight aluminum construction results in motors that deliver superior performance and reliability.

Longevity: Efficient thermal management and reduced wear and tear lead to extended motor lifespans, further enhancing cost-effectiveness.

Regulatory Compliance: As industries strive to meet stringent energy efficiency standards, these motors enable compliance with regulations and guidelines.

Challenges and Future Developments

While aluminum shell high-efficiency asynchronous motors offer substantial benefits, challenges such as material cost and manufacturing complexity remain areas of consideration. Ongoing research aims to optimize manufacturing processes and materials to make these motors more accessible and cost-effective.

While aluminum shell high-efficiency asynchronous motors offer a multitude of benefits, certain challenges need consideration. The choice of materials, such as aluminum, can impact thermal performance and require careful engineering to manage potential overheating. However, continuous research and development efforts are focused on refining motor design, insulation, and cooling systems to mitigate challenges and ensure reliable operation.

Technological advancements in material science, motor design, and manufacturing techniques continue to shape the landscape of aluminum shell high-efficiency asynchronous motors. Innovations in thermal management, insulation materials, and motor control systems are driving the development of even more efficient and reliable motor solutions.

English

English 中文简体

中文简体 عربى

عربى